Pivoted Weigh Screw for Blending Plant Case Study

ModQuip was tasked with designing and constructing a continuous weighing and blending system to combine powdered materials from four silos into blended bins for final bagging.

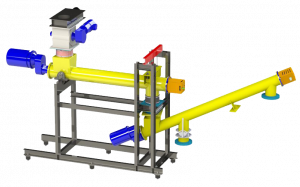

As part of ModQuips supply and service program, our team modified a series of screw conveyors to operate as pivoted weigh screws for a WA cement plant relocation. The project required a highly precise system that was able to blend a variety of powdered materials, the system would need to be able to continuously blend two materials at a site requested demand rate into a holding bin. The accuracy of each screw needed to ensure the final mix ratio is correct.

Working closely with the customer’s project engineers and our sister companies Inquip and Automation & Control, ModQuip coordinated the design and supply of a multipath silo-to-blending station system. The installation featured seven feed screws and seven pivoted weigh screws, linked to a continuous weigh control with seven HMI stations and site PLC interface.

Operating from four silos, each fitted with a bin activator and twin outlet, material was delivered to the feed screw, which then transferred product to the pivoted weigh screw. ModQuip equipped the screws with pivot load cell encoders, enabling the electronic system to measure and monitor screw speed and material weight within to calculate continuous throughput rates.

ModQuip provided onsite support throughout installation and commissioning, assisting the site team with capture test calibration to ensure the system performed accurately and reliably.

ModQuip successfully delivered the equipment on time and within budget. In collaboration with our sister company, Automation & Control, and through close coordination with site operators, the system was fully installed, commissioned, and calibrated to achieve the required blending performance and mixing precision – ensuring consistent product quality across the operation.